Posted by admin , on Nov, 2015

The American Petroluem Institute or API has set specification guidelines for connectors, according to the PetroWiki. These 3 tubing connectors are often used as tubing joints: the external-upset tubing and coupling and then the non-upset tubing and couplings. Lastly, there’s the integral-joint tubing as well. All three types share round thread forms. There’s are good chance that they’re designed with 8 or 10 threads/in, though that depends wholly on the size as well. For cases where casing is turned into tubing, then a number of connections are possible and can be observed.

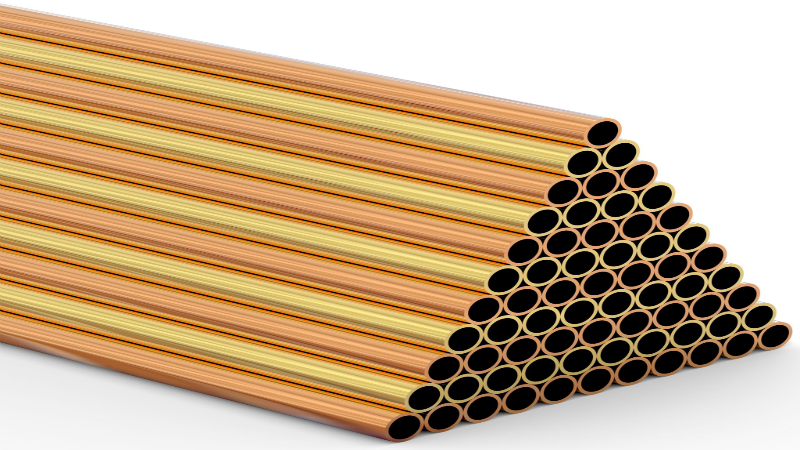

Types of Tubing

* External Upset End: External upset end or the EUE tubing connection is the most commonly used of all three. You can count on it to deliver a reliable connection in many wells. In an EUE design, the strength in tension and pressure is bigger than that of the body of the pipe. That makes for an efficient communication, at 100 percent.

* Non Upset End: NUE tubing connectors are used less frequently than EUE tubings, though it does cost less than an EUE, comparatively speaking. The price gap isn’t too big though but the strength of the material is less than the EUE. Which is why for high-pressure applications, EUEs still win.

* Integral Joint End: This tubing type is well-known for having a joint strength that’s less than the minimum yield of its body. That typically restricts its use. It’s ideal for use, though, when put inside larger tubing strings. This is also a common sight in wells where it acts as unloading or vent strings.

* Non-API Connections: Other non-API connections are also available in the market. If you need joints in cases where leak resistance or clearance needs to be greater than the one API connections are able to provide, then these non-standard joints have you covered.

Manufacturing Process

Any tubing designed to match API specifications goes through either a seamless or electric-weld process. Both processes are applicable for most gas as well as oil services.

Function and Quality

Choosing tubing connectors depend on two basic factors: function and quality. What do you need the connectors for? When you have this figured out, then you already have a solid idea on what types to go for. Given the many types of connector ranges available in the market, you won’t have to worry about choice. It won’t be a matter of finding enough choices, but of finding the one that will keep you busy.