Posted by admin , on Feb, 2015

You can get all of your plastic milling needs met when you outsource to nearby companies. When your company needs plastic milling it is best to look for the most cost effective resource. Buying from local companies may not meet all of your needs especially given higher prices and fewer working hours that are offered by local companies. However, when you turn to an outsourced alternative you may be able to reduce your company’s costs and still get all of your prototyping needs done on time. No longer does your company need to worry about meeting that deadline. No longer will you stress about the rising costs of production. You can find everything to meet your prototyping needs for any project large or small when you utilize the resources and professional companies that are located nearby.

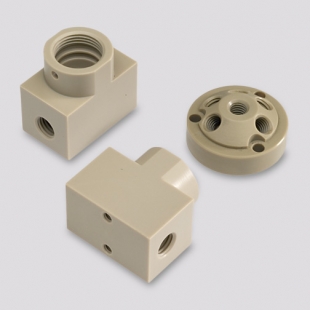

In addition, if you outsource your plastic milling needs to a company nearby, you can rest assured that your prefect prototype will arrive on time and on budget, saving you and your company stress, time and money. Prototyping is an alternate technique applied in creating prototype castings that copy many grades of rubber along with molded components like PA & PP. Prototype manufacturing is assumed to be a very cheap technique in terms of cost, with reference to other casting methods. Plastic milling is another great alternative that you can have completed on your behalf at a low cost. You can use this to ensure your company has everything it needs, regardless of your particular type of industry.

Ask Questions

There are many things you can learn from plastic milling manufacturing and if you need to create casts then you should consider learning about vacuum casting and other prototype manufacturing services that are available. Ask questions if you have them. A good company will be there to answer them. A good company will be able to tell you what materials and methods are best suited for your needs and what it will cost up front. Do not settle for less.

Look for Guarantees

Quality control is also guaranteed since your completed prototype will be inspected as soon as it is done and can be reworked if necessary while still meeting your deadline. This guaranteed quality control ensures that the prototype you ordered would be up to your company’s exacting standards since any problems will be addressed before shipping. Once your prototype has passed inspection, it can be shipped anywhere in the world, to your office, factory or even the site of your presentation, where it will be waiting for you when you arrive for the big meeting.